The Textile Industry and the Self-Acting Mule

June 2025

Advancement

Richard Roberts invented the self-acting spinning mule in 1822, set himself the task of designing a self-actor, a self-acting or automatic spinning mule. This revolutionised production in the spinning and weaving industries. The mule in 1820 required manual assistance from 7 people to spin a coherent thread. To operate the mule the overseer oversaw the workings of the mule, and then there were two piecers, usually two young women with their hair tied back for safety, and two doffers who doffed the material. There were also two scavengers, children who were small enough to pick up any bits of cloth that dropped underneath the machine. This was stopped in 1833 by the government's Factory Act. Children had to be at least 9 years old to work in factories.

The self-acting mule needed one overseer to ensure that it was running correctly, however it did not need manual assistance to work. The early spinning mules were handmade by individual craftsmen with metal working skills, sometimes leading to significant differences between individual machines.

Early Spinning Mules

The mule at Leeds Industrial Museum was originally made in 1904 by Plat Brothers and Co LTD. The mule's 300 spindles were designed to spin fibres into yarns and when it was operating the mule created a distinct amount of noise. The mule was so loud that workers had to use sign language to communicate. Workers also suffered damage to their hearing. Unrecorded injuries were common. The Health and Safety at Work etc Act didn't come into place for another 70 years.

Museum records show that James Ives and CO Ltd. of Leafield Mills in Yeadon owned the mule. The mule was most likely used at James Ives Manor Mills, the James Ives company was established in 1848. The James Ives Company bought the Manor Mills in 1911. The mill closed in 1980 and was demolished in 1981.

The self-acting mule at Leeds Industrial Museum produced material that would be used by Hainsworth’s to produce traditional military regalia mostly for ceremonial occasions in the UK and abroad. The clothing produced was of the highest quality.

The impact of the self-acting spinning mule was significant, it fuelled the mass production of yarns and textiles, which led to the establishment of large-scale factories and the rise of industrialisation. The most positive impact was how it improved people's lives financially and practically.

Health and Safety

Previously, hand-operated machines such as sewing machines offered limited output. This early textile production was carried out in cottage industries. The mule could produce textiles at a very fast and efficient rate compared to the older machines. There were, howeve,r some risks to health for those operating a mule. The staff operating the mule could catch their clothing or limbs in the spindle or the carriage, this was due to the machine's rapid movements. The hands, fingers, arms, and head were vulnerable to injuries. These injuries varied in severity from slight to fatal and had various causes. Contributing factors to the risk of injury were a lack of safety devices and poor working conditions.

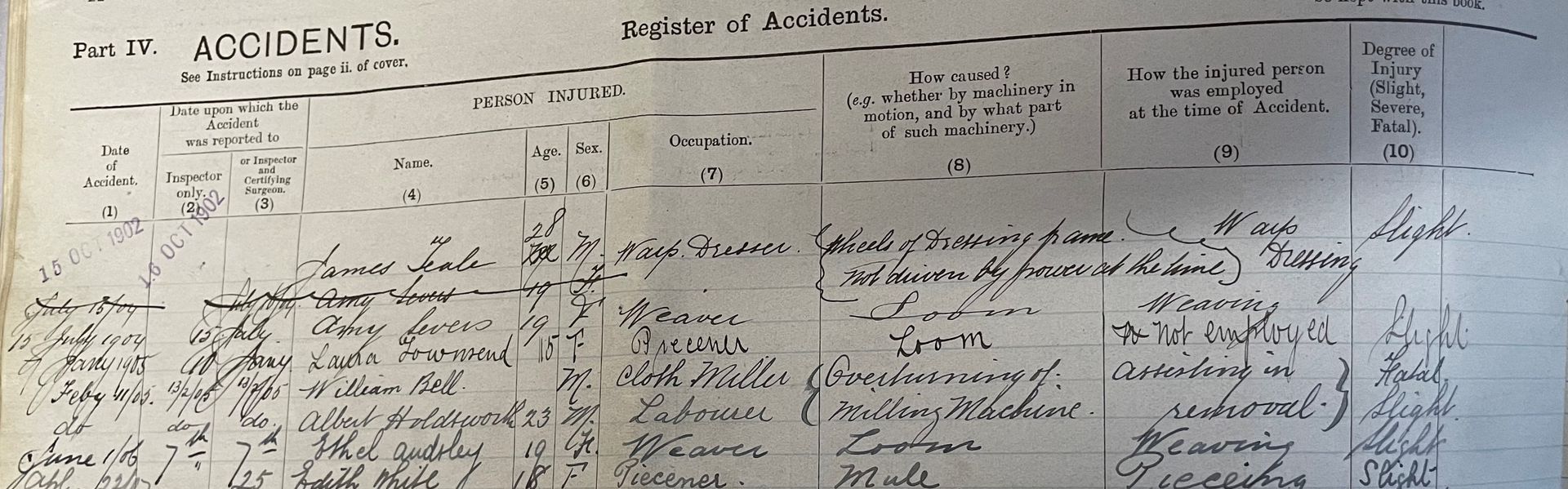

Below is an image of the incident book from 1902. Incidents like these would be recorded in more detail in modern factories. As we can see from the image below, most of the workers who were injured were weavers; a couple were injured while operating the loom, and others were injured while operating the loom.

Impact

The widespread use of the self-acting mule in factories during the Industrial Revolution had a major impact upon the populace of Leeds, in which wool played a huge role in creating jobs through manufacturing. As can be seen, the self-acting mule had many positive effects in terms of the rate of production, leading to significant economic advantages; however, the risk of injury was very high in the 1800s, the health and safety legislation at the time was limited and the technology for textile manufacturing was not as advanced as it is today.

The impact of the self-acting spinning mule was significant; it fuelled the mass production of yarns and textiles, which led to the establishment of large-scale factories and the rise of industrialisation. The most positive impact was how it improved people's lives financially and practically.

Modern Machinery would look to increase the volume of clothing production and reduce the risks of injury as we shall see in the next part of this blog.

By Liam Whetstone, Careers For All participant